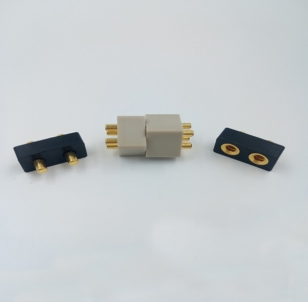

The internal metal end pin components of the board-to-board connector are mostly composed of some electroplated parts, so generally in the storage package of the connector, the connector must be sealed, do not directly expose to the air contact, otherwise the connector will be affected by the humidity of the air, and then cause the internal moisture oxidation of the component. So let's learn about what aspects you need to pay attention to when purchasing board-to-board connectors and how to maintain them daily.

1. The load voltage of the investigation board-to-board joint cannot exceed 50% of its additional voltage.

2. The device size of the board connector is a plug, and the length of the soldering pin soldered to the PCB is required to expose the PCB board segment greater than 0.5mm.

3. Board-to-board connectors with high precision, try to choose the type with positioning pin under the condition that the PCB space is agreed, which is convenient for operation when the hand I is welded.

4. See if there is a foolproof design.

5. Whether the materials used contain lead.

6. Touch resistance: small volume board-to-board connector, small contact pressure, low current, low voltage occasions, it is recommended to use gold-plated or silver-plated connectors to prevent the film resistance from affecting the signal.

7. Pay attention to investigate whether the height of the board-to-board connector after the connector reaches the welding height of the components around the PCB. The cooperation height of the circuit board must be greater than the welding height of the components around the PCB to ensure that there is a certain margin and no interference. In particular, it should be noted that the PCB may produce high errors after soldering.

How to maintain it daily:

1. In the operation of the board-to-board connector, it is necessary to ensure that the board-to-board connector device is firm and reliable, otherwise the fixed and unstable situation of the connector will lead to abnormal separation between some pins and jacks in the use, resulting in serious consequences of the suspension of power transmission and signal control of the control system.

2. Under normal circumstances, the end pin of the board-to-board connector is one of its main center components, and its effect is transmitted to the contact corresponding to its matching connector through current or signal. Therefore, generally when the connector is plugged in, it is necessary to pay attention to the action not to use too much force, otherwise too much force will easily form the internal end pin of the connector and reduce the service life. The second situation is that the end pin of the board-to-board connection may be broken or damaged, which is also related to the entire connection and cannot be used.

3, board-to-board connector is generally in the wiring, do not unplug the connector at will, because the connector in the process of operation, will be in the transmission between larger current, if the connector is rushed, on the one hand, it is easy to form the data between the equipment or abort abnormal situation, such as in the operation of the connector, will be in the transmission of larger current, if the connector is rushed, it is easy to form the data between the equipment or abort abnormal situation.

4. If the board-to-board connector is used for a long time, it is necessary to regularly maintain the connector, such as the surface of the connector and the inside of the end pin will accumulate some dust and debris, if not dealt with in time, it will affect the performance of the connector, and it is also easy to lead to problems. The next thing to check is whether the connector is damaged, and once found, it needs to be replaced in time, so as not to pose a great safety hazard to the use. Spring manufacturers

5. The mutual effect of the board-to-board connector on the force of entering and pulling out is easy to form the loss of the metal sheet in the connector. So how to generally reduce the plug-in wear of board-to-board connectors? Therefore, in daily life do not need connectors, do not mess with the connector, secondly, the connector inside the connector for regular end pin maintenance, if used for a period of time, must be removed the end pin, can use some eraser to remove the surface of the dirt or debris, and then effectively extend the life of the connector.

The above explained content is about the purchase of board-to-board connectors need to pay attention to what aspects and daily maintenance of the relevant content, I hope to read after can help you, if you want to know more about board-to-board connectors, you can consult online customer service, we will serve you sincerely.