Slanted coil spring: Mechanical seal is a safe and reliable sealing method, which is widely used in fluid sealing. During the sealing process, there is no direct contact with the shaft to cause wear, so better sealing can be obtained, leakage is reduced, and the safety and reliability of the machine are improved. The mechanical seal structure of the inclined ring spring selects the beveled coil spring as the elastic compensation element of the mechanical seal, and uses the characteristics of large elastic deformation and small elastic change of the beveled ring spring to make the mechanical seal obtain a better sealing effect.

In some special occasions, such as high temperature, high pressure, high speed and other mechanical seal conditions, the performance of ordinary cylindrical tightening coil spring mechanical seal is difficult to meet the requirements. In order to get accustomed to the needs of modern mass production, an axial end face touch mechanical seal spring, that is, an inclined coil spring, also known as spring finger touch and finger touch spring. The main feature of the bevel coil spring is the selection of the axial tightening ring bevel ring as the compensation element, and the spring push type replaces the traditional mechanical seal. During the tightening process, each coil in the annular spring coil acts in parallel, tightens axially, and rotates in the circular direction. The mechanical seal of this structure relies on the elastic force supplied by the bevel coil spring to push away the axial sliding of the static ring, compensate for the axial orientation error caused by wear, and can also buffer oscillations and pressure changes under messy working conditions. Then maintain the balance of axial force between the sealing pairs, form a better and more stable sealing film between the sealing friction pairs, and achieve dynamic sealing under the pressure of the sealing film itself.

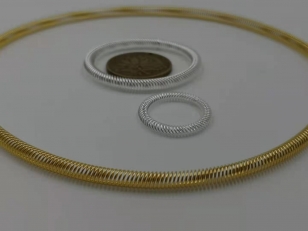

Structural features of the bevel coil spring:

The coils of the inclined coil spring are small in size and quantity, and the current capacity and skill economy are high. In the case of large tolerance error, the beveled coil spring can still maintain a constant force, which can reduce the deformation of the spring and compensate for the impact of surface unevenness and bonding tolerance to the greatest extent. In addition, the inclined coil spring can withstand a certain tightening deformation, so that it can work normally in harsh working environments such as oscillation and shock.

According to the different structural characteristics of the inclined coil spring, the inclined coil spring can be divided into radial and axial, and the direction of the tightening force of the radial inclined coil spring is perpendicular to the centerline (along the radius of the circle), so this spring is mainly used for connecting parts. Slash coil springs, which have an axial tightening force parallel to the centerline (in the direction of a circle), are generally used as seals.